New Energy Vehicle Battery Core Aerogel Insulation Board

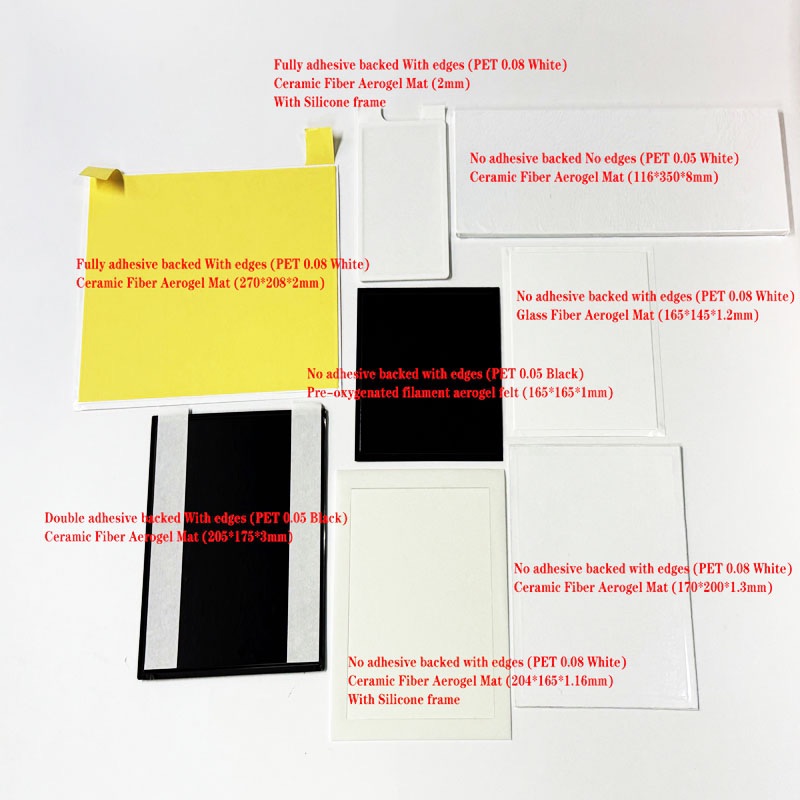

| Model NO. | Ceramic Fiber Aerogel Mat | Width | Customizable25ºC) |

| Thickness | Customizable | Thermal Conductivity | Temperature 25ºC 100ºC 300ºC 500 |

| Bulk Density | 0.19g/cm3 | Compressive Strength (Kpa) | 120kpa |

| Volumetric Water Absorption (%) | 0.62% | Temperature Resistance (°c) | 1250ºC |

| Transport Package | Rolls | Specification | Customized 2mm |

| Trademark | Skyboys | Origin | Zhejiang China |

| HS Code | 5602900000 | Production Capacity | 100000 |

Product Description

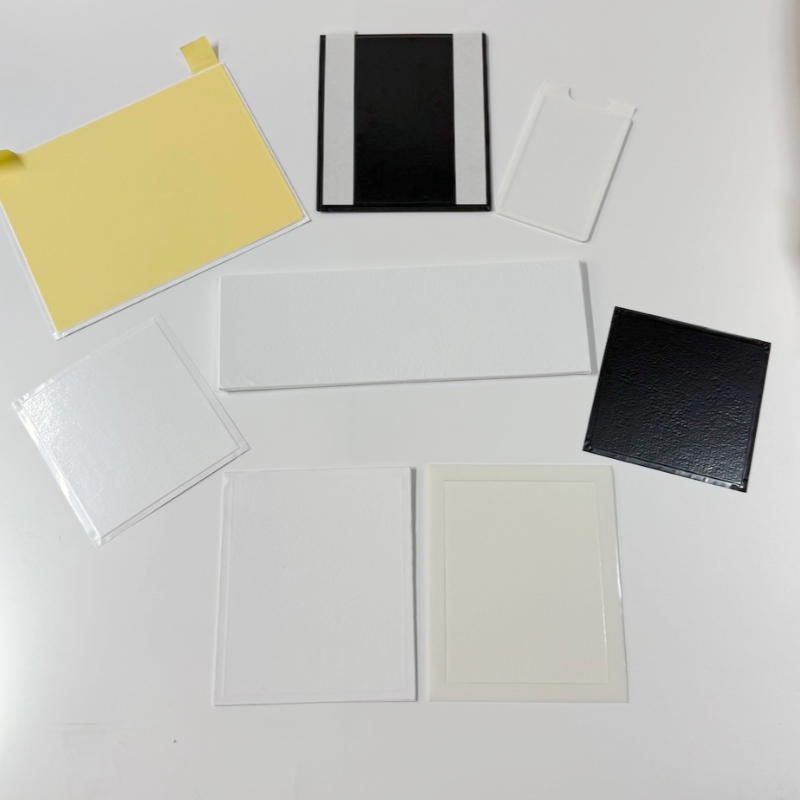

| Product Category | Glass Fiber Battery Aerogel | Glass Fiber Wet-Process Battery Aerogel | Ceramic Fiber + Silicon Dioxide Aerogel |

| Composition | Glass Fiber + Silicon Dioxide Aerogel | Glass Fiber + Silicon Dioxide Aerogel | Ceramic Fiber + Silicon Dioxide Aerogel |

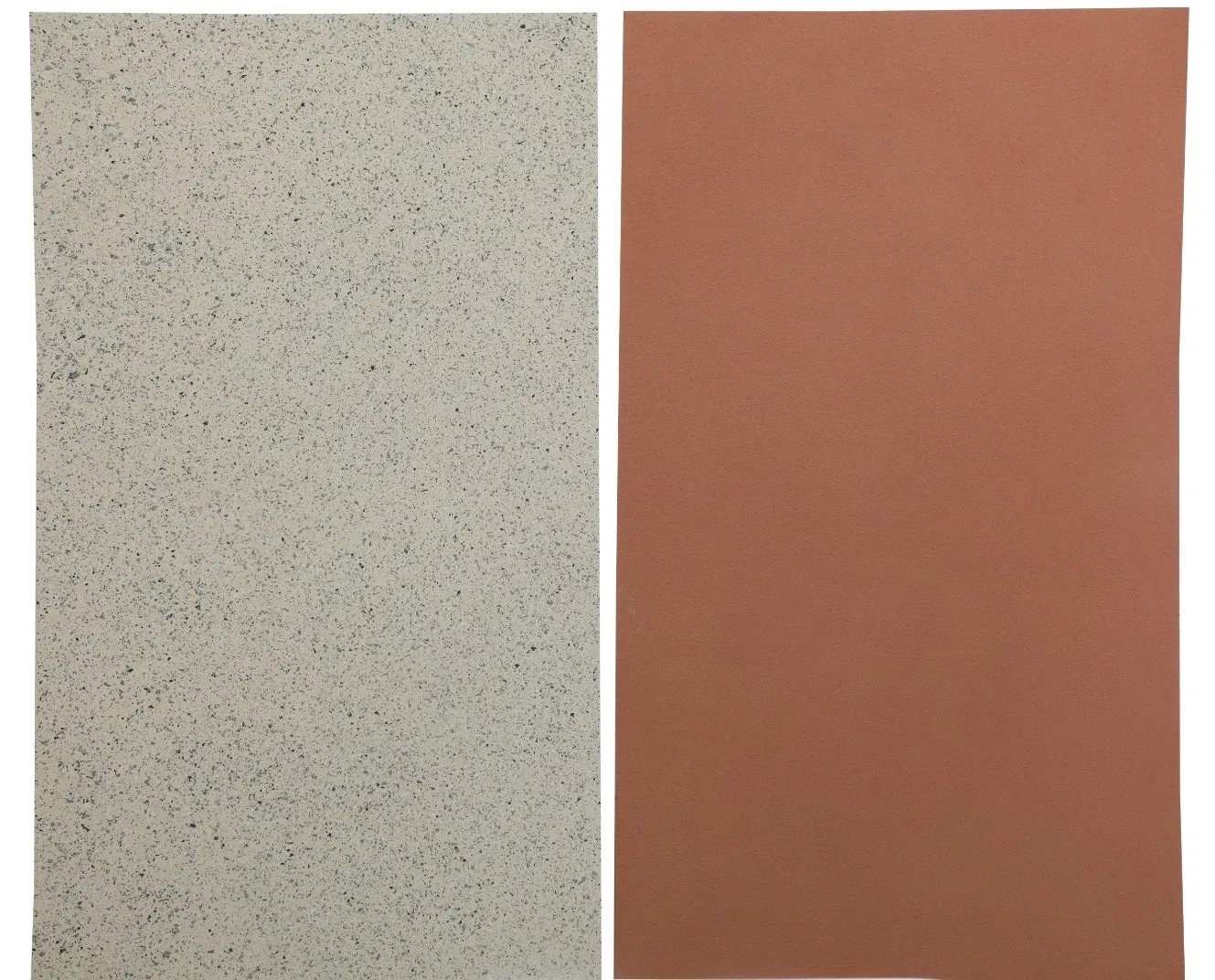

| Color | White | White | White |

| Application | Energy Storage / Electric Furnaces / Petrochemicals | New Energy Vehicles | New Energy Aircraft / New Energy Ships / Industrial Furnaces / Electric Furnaces / High-Speed Trains / Shield Tunneling Machines / Wearable Devices / Communication Base Stations / Transportation / Household Appliances, etc. |

| Product Model | XK-BX01 | XK-BX02 (UL Certified) | XK-BX03 |

| Thermal Conductivity | ≤ 0.021 W/m·K | ≤ 0.021 W/m·K | ≤ 0.021 W/m·K |

| Compression Resilience | > 90% | > 90% | > 90% |

| Thermal Insulation Performance | 700ºC≤350ºC(3.5mm) 600ºC≤270ºC(2.0mm) 500ºC≤250ºC(1.7mm) | 700ºC≤250ºC(3.5mm) 600ºC≤170ºC(2.0mm) 500ºC≤150ºC(1.7mm) | 700ºC≤300ºC(3.5mm) 600ºC≤220ºC(2.0mm) 500ºC≤200ºC(1.7mm) |

| Insulation | ∞ | ∞ | ∞ |

| Withstand Voltage | Leakage current under all conditions < 0.001mA | Leakage current under all conditions < 0.001mA | Leakage current under all conditions < 0.001mA |

| Hydrophobicity | > 98% | > 98% | > 98% |

| Flame Retardant | V-0 | V-0 | V-0 |

Chemical FilmForming Aerogel Fireproof Thermal Insulation Felt

Utilizing nanoaerogel and glass fiber composite technology combined with chemical filmforming processes, this product is an innovative material offering superior fireproofing and thermal insulation.

The aerogel composite material is composed of nano aerogel, glass fiber, pre oxidized fiber and other basem aterials, perfectly combining the aerogel with excellent performance and flexible base materials, maximizingthe light weight, heat insulation and other characteristics of aerogel, and endowing gel with flexibility andtoughness.

Core Technologies:

Chemical Film Coating: Replaces traditional supercritical extraction, enhancing aerogel penetration and adhesion.

HighTemperature Atmospheric Drying: Reduces production costs while improving product stability.

| Item parameter | |

| Thermal Conductivity | 0.018-0.023 W/(m·K) |

| Fireproof Rating | A1 (GB/T 25352-2010) |

| Operating Temperature | -200°C to 650°C |

| Long-Term Shrinkage | ≤1% (650°C) |

| Density | 160-240 kg/m³ |

| Water Absorption | ≤0.02% |

| 10mm products, Civil Aviation Administration test 1000C, 30 minutes of open flame does not burn through, the back heat flow value is very low | |

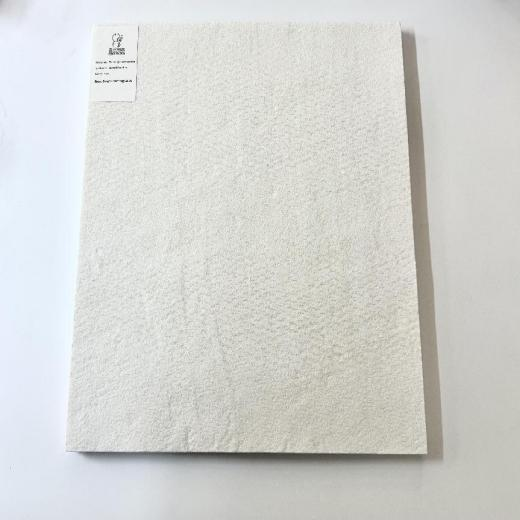

Glass Fiber Chemical Film-Formed Aerogel Fireproof Insulation Felt

| Attribute | Specification |

| Width | Customizable |

| Thickness | Customizable |

| Color | White |

| Max Operating Temperature | 1200°C |

| Thermal Conductivity @ 25°C | ≤0.021 W/m·K |

| Thermal Conductivity @ 300°C | ≤0.036 W/m·K |

| Vibration Compression Set Rate | ≥-1.0% |

| Heat Aging & Multi-Cycle Stability | ≥-0.0% |

| Compression Resilience | ≥90% |

| Flammability | A Grade (Completely Non-combustible) |

| Hydrophobic Performance | ≥99% |

Burn-Through Resistance Test Results

| Test Item | 1mm | 2mm | 3mm |

| Burn-Through Time | 20s | 5 min 23s | 15 min |

10mm product tested by Civil Aviation Authority: Withstands 1000°C for 30 minutes without burn-through, with minimal backside heat flow.

Pre-Oxidized Fiber Chemical Film-Formed Aerogel Fireproof Insulation Felt

| Attribute | Specification |

| Width | Customizable |

| Thickness | ~5mm |

| Color | Black |

| Thermal Conductivity @ 25°C | 0.022 W/m·K |

| Dielectric Strength | <0.1mA |

| Insulation Resistance | ≥500Ω |

| Flame Retardant Level | V0 |

| Hydrophobic Performance | ≥98% |

| ROHS 2.0 | Compliant |

| REACH | Compliant |

Core Product Advantages

Core Product Advantages

Core Product Advantages

1)Exceptional Thermal Insulation

UltraLow Thermal Conductivity: 0.018-0.023 W/(m·K) (1/5 of traditional materials), effectively blocking heat transfer.

Wide Temperature Range: Operates from 200°C to 650°C, maintaining stability in extreme environments.

2)TopTier Fire Safety

A1 Fireproof Certification: Complies with GB/T 253522010, withstands direct flame at 1200°C-1600°C for 30 minutes without burning through.

Hydrophobic & MoistureResistant: 3D network structure prevents water ingress, ensuring no deformation or settling over time.

3)LongTerm Durability

Weather Resistance: UVresistant, with a lifespan exceeding 20 years.

HighTemperature Stability: Shrinkage rate ≤1% at 650°C, no melting or powdering.

4)Lightweight & EcoFriendly

UltraLight Density: 160-240 kg/m³, reducing equipment weight and simplifying installation.

100% Recyclable: Zero toxic emissions during production, fully recyclable after use.

Application

Application

Application

Building and Construction: Used for insulating walls, roofs, and floors to improve energy efficiency and reduce heat loss.

Industrial Insulation: Applied to pipes, tanks, and equipment in industrial settings to maintain process temperatures and prevent heat loss.

Automotive and Aerospace: Utilized in vehicles and aircraft to provide lightweight, high-performance thermal insulation, reducing energy consumption and improving fuel efficiency.

Clothing: Incorporated into high-performance outdoor and protective clothing to provide superior thermal insulation while maintaining lightweight and flexible properties.

Electronics: Used to manage heat in electronic devices and systems, protecting components from overheating.

Oil and Gas Industry: Employed for insulating pipelines and equipment to maintain the temperature of transported fluids and prevent freezing or heat loss.

Cryogenics: Applied in cryogenic insulation systems to minimize heat transfer and maintain extremely low temperatures.

Services And Technologies

Cost Reduction: Chemical filmforming process reduces production costs by 30% compared to traditional drying methods.

Performance Enhancement: Fireproof and thermal insulation coefficients improved by 50% at the same thickness.

Customization: Supports thickness (3-50mm) and density (60-200kg/m³) customization.

Strong thermal insulation

Strong thermal insulation

The thermal insulation performance of air gel felt is far superior to that of conventional materials. Its interior is a nano porous structure with high porosity and small pore diameter, which can effectively block the flow of air.

The thermal conductivity coefficient is extremely low, which can effectively block the transfer of heat flow, greatly improving the thermal efficiency of the equipment. For example, its thermal conductivity is only several times that of traditional materials . When the test temperature is -25 ºC, the thermal conductivity of glass fiber air gel felt is only 0.021W/m.k.

Hydrophobic fire prevention

Aerogel felt is hydrophobic, which can effectively prevent moisture from entering into pipes and equipment. At the same time, it generally has A1 level fire resistance performance for buildings, with good fire resistance performance. Its unique three-dimensional network structure avoids the phenomenon of significant decrease in insulation effect caused by sintering deformation and settlement of other insulation materials during long-term high-temperature use.  Stable and durable

Stable and durable

Aerogel felt has extremely high durability and can maintain its performance for a long time in harsh environments. For example, it has a shrinkage rate of ≤ 1% when used for a long time at 650 ºC, and there is no melting sintering or powdering phenomenon. Aerogel is an inorganic material. It does not age under long-term ultraviolet radiation, has good weather resistance, and has a service life of more than 20 years.

Lightweight and environmentally friendly

Due to the nanometer thickness and lightweight characteristics of aerogel, the density of aerogel felt is usually between 160~240 kg/m ³, which greatly reduces the weight of the equipment, making it easier to carry and install the equipment. The production process is environmentally friendly, free of harmful substances, and no toxic substances are generated during use. After the service life, the aerogel felt can be completely recycled, reducing the impact on the environment

Packaging & Shipping

Fast Delivery: Samples shipped within 3 days; bulk orders delivered in 15-20 days.

Fast Delivery: Samples shipped within 3 days; bulk orders delivered in 15-20 days.

Technical Support: Installation guidance and lifetime aftersales consultation.

Ceramic Fiber Chemical Film-Fo...

Ceramic Fiber Chemical Film-Fo...  Wet-process Glass FiberAerogel...

Wet-process Glass FiberAerogel...  Needle-Punched Glass FiberAero...

Needle-Punched Glass FiberAero...  Aerogel Panel

Aerogel Panel  OEM Cherry Wood Grain Antibact...

OEM Cherry Wood Grain Antibact...  Cement-Based Aerogel

Cement-Based Aerogel  Aerogel Fireproof And Heat-Ins...

Aerogel Fireproof And Heat-Ins...  Thermal Insulation Integrated ...

Thermal Insulation Integrated ...  New Energy Vehicle Battery Cor...

New Energy Vehicle Battery Cor...  Aerogel Explosion-Proof Fire B...

Aerogel Explosion-Proof Fire B...  Water-Based Aerogel

Water-Based Aerogel