Aerogel Industry Boom: From Aerospace to Green Building & EVs

Date: 2025-05-27 Categories: News Hits: 295

1. Under the Carbon Neutrality Push: Aerogel Gains Strategic Material Value

As China and many countries accelerate their 'dual-carbon' (carbon peaking and neutrality) goals, the demand for high-performance insulation materials is surging. Silica aerogel, known for being the lightest and most thermally insulating solid material, is now being re-evaluated across industries.

According to Zhiyan Consulting, China’s silica aerogel market reached RMB 2.173 billion in 2023, growing 19% year-over-year. The market is projected to exceed RMB 4 billion by 2025, indicating a high-growth trajectory.

2. Huge Demand from Building Sector – Estimated to Hit RMB 2 Billion by 2025

According to ccia.xin, the demand for aerogel in the building insulation sector alone is expected to hit RMB 2 billion by 2025. Aerogel’s fire resistance (UL94-5VA / GB Class A), ultra-low thermal conductivity, light weight, and long lifespan make it ideal for applications in energy-efficient construction.

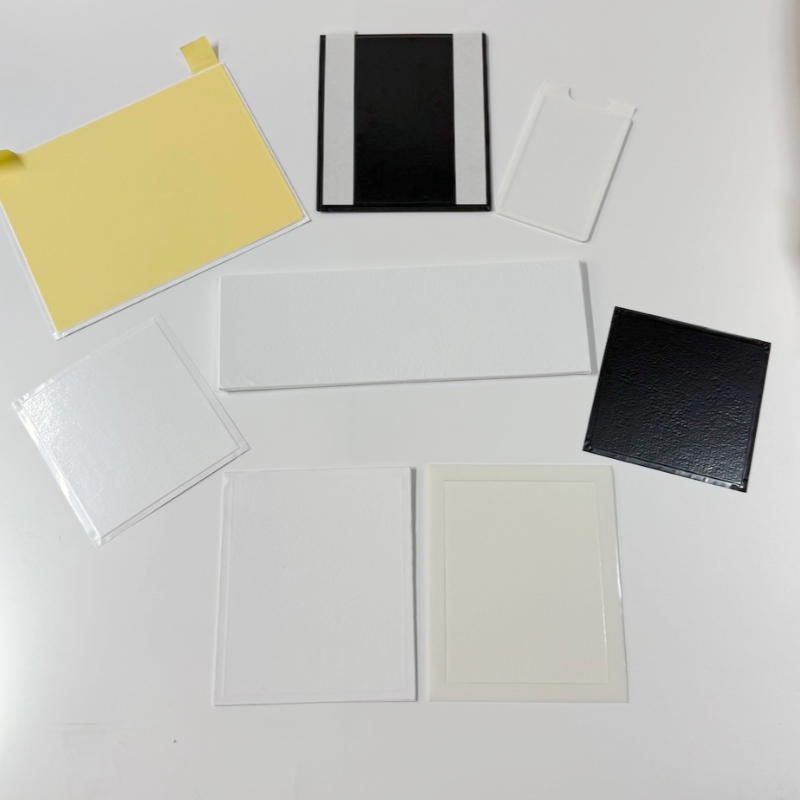

Compared with traditional insulation materials like EPS or XPS, aerogel products—especially composite panels, fiberglass blankets, and coatings—offer higher safety and thermal performance. These materials are increasingly used in passive buildings, retrofits, prefabricated buildings, and data centers.

3. From Aerospace to Everyday Use – Aerogel Is Going Mainstream

Originally developed for aerospace and defense applications, aerogel is now penetrating mass-market industries. It’s being used in:

- Petrochemical pipeline insulation

- Subway and rail transit insulation

- Commercial appliances (e.g., water heaters, refrigerators)

- Residential building retrofits (e.g., roof/wall insulation)

With industrial maturity and better pricing, the cost of aerogel fiberglass blankets is now under $10 per m², making it viable for large-scale use.

4. EV Safety Is Driving Demand – Aerogel as the Standard Thermal Barrier

As EV battery density increases, the risk of thermal runaway becomes more critical. Aerogel is now widely adopted by top EV battery makers such as CATL and BYD.

Common applications include:

- Insulation pads between battery modules

- Thermal barrier layers inside battery packs (up to 1200°C)

- Flexible aerogel films for wire and harness protection

Aerogel provides reliable safety insulation, fire protection, and thin-form factor, making it indispensable in battery thermal management.

5. Summary: Aerogel Is Entering Its Golden Decade

Aerogel is no longer just a 'high-end niche material'—it’s quickly becoming a new standard for modern insulation.

From green building to energy storage, from extreme heat to everyday environments, aerogel is reshaping how we think about insulation and fireproofing.

At SkyBoys (Hangzhou) Technology Co., Ltd., we specialize in delivering UL94-5VA certified aerogel composite solutions—fiberglass blankets, ceramic fiber blankets, and all-in-one insulation panels—to global contractors, wholesalers, and system integrators.

For technical data sheets, case studies, or samples, contact us:

Email: skyboys.kimi@gmail.com

WeChat / WhatsApp: +8613626519690

Company: SkyBoys (Hangzhou) Technology Co., Ltd.

Ceramic Fiber Chemical Film-Fo...

Ceramic Fiber Chemical Film-Fo...  Wet-process Glass FiberAerogel...

Wet-process Glass FiberAerogel...  Needle-Punched Glass FiberAero...

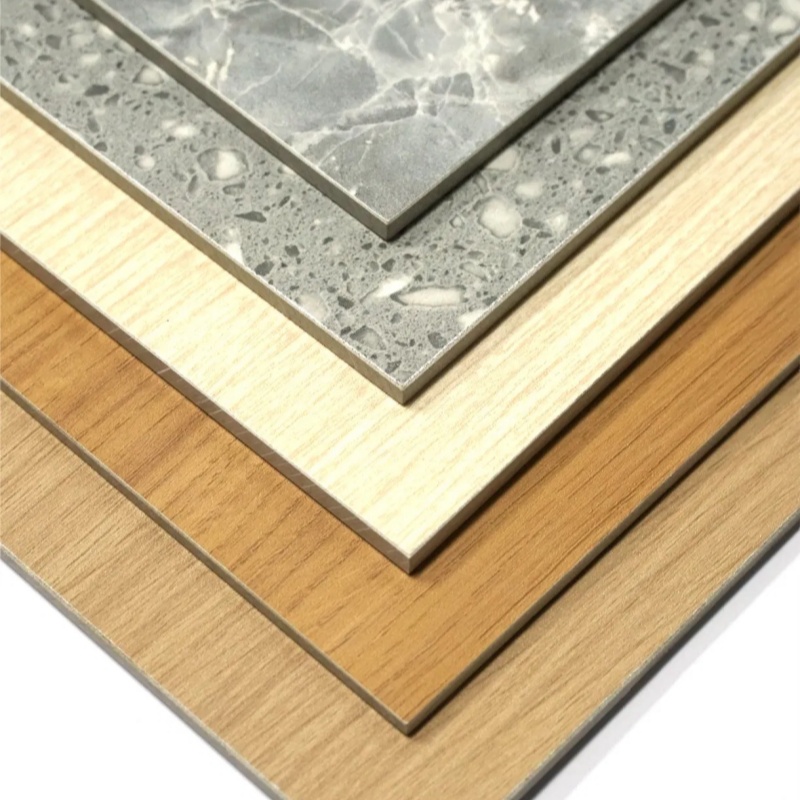

Needle-Punched Glass FiberAero...  Aerogel Panel

Aerogel Panel  OEM Cherry Wood Grain Antibact...

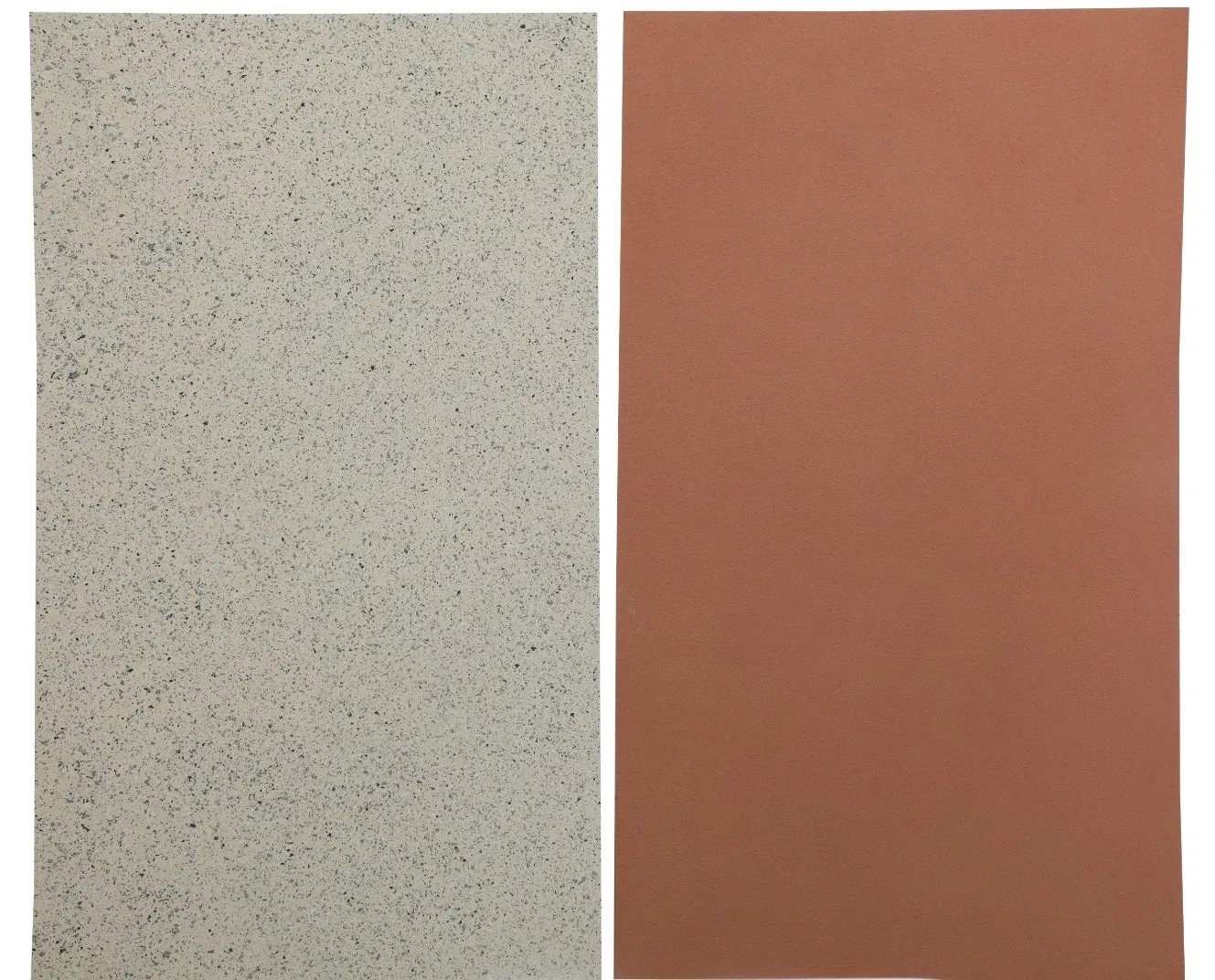

OEM Cherry Wood Grain Antibact...  Cement-Based Aerogel

Cement-Based Aerogel  Aerogel Fireproof And Heat-Ins...

Aerogel Fireproof And Heat-Ins...  Thermal Insulation Integrated ...

Thermal Insulation Integrated ...  New Energy Vehicle Battery Cor...

New Energy Vehicle Battery Cor...  Aerogel Explosion-Proof Fire B...

Aerogel Explosion-Proof Fire B...  Water-Based Aerogel

Water-Based Aerogel