What Is Aerogel Fiberglass Felt Used For?

Date: 2025-05-27 Categories: News Hits: 261

If you're like me, you’ve probably asked—why are more contractors switching to aerogel fiberglass felt? I used to rely on traditional insulation too, until I saw what this material could actually do.

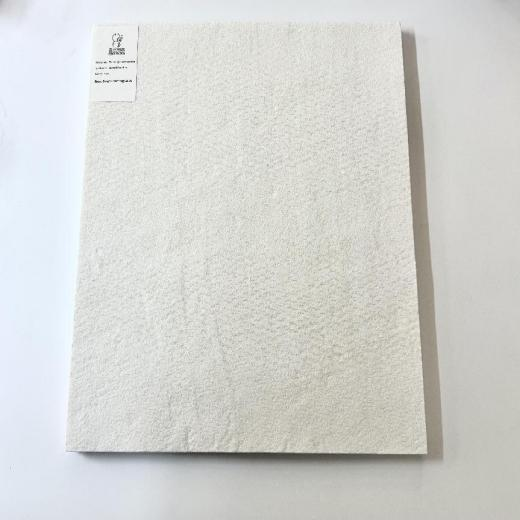

Aerogel fiberglass felt is mainly used in industrial insulation, fireproof construction, high-temperature environments, and energy-efficient buildings due to its excellent thermal resistance, lightweight nature, and fire retardant properties.

It’s not just about keeping heat out or in. For modern construction—especially in factories, warehouses, or areas requiring both safety and efficiency—aerogel felt is becoming the first choice. Let me explain why.

How Is Aerogel Felt Applied in Industrial Insulation?

I remember when one of our Middle East clients asked us if this “aerogel stuff” was worth the cost. At first, I had doubts too. But then I saw how traditional insulation simply couldn’t hold up in extreme conditions.

Aerogel fiberglass felt is widely used in pipelines, tanks, equipment, and HVAC systems in industrial plants because of its low thermal conductivity and resistance to moisture.

Let’s break this down. In most factories, large amounts of energy are lost due to poor insulation. This doesn’t just waste money—it also affects machinery performance. Aerogel felt helps reduce heat loss more effectively than materials like rock wool or foam.

Key Properties for Industrial Use

Property | Aerogel Felt | Traditional Insulation |

Thermal Conductivity | 0.018–0.023 W/m·K | 0.035–0.045 W/m·K |

Thickness Required | Less | More |

Weight | Lightweight | Heavy |

Water Resistance | Excellent | Poor |

Because it’s thin but effective, contractors can save space in confined industrial areas. That’s a game changer for large facilities with complicated equipment layouts. It also stays dry, which prevents corrosion of metal surfaces—a big concern for many factory owners.

This is why many importers I work with—especially from South Asia—are replacing bulky insulation rolls with aerogel felt for better results and less labor.

Can Aerogel Felt Be Used in Fireproof Construction Projects?

I once walked through a newly built warehouse where the insulation failed within the first six months due to a fire incident. That client never made the same mistake again.

Yes, aerogel fiberglass felt is used in fireproof projects because of its Class A fire rating, non-combustible nature, and ability to maintain structure at temperatures above 1000°C.

For factories and warehouses, fireproofing isn’t optional—it’s mandatory. Materials like polyurethane foam can catch fire or release toxic fumes. Aerogel doesn’t.

Common Applications in Fireproof Projects

Application Area | Aerogel Usage Advantage |

Fireproof Walls | Maintains insulation in flames |

Steel Frame Protection | Delays structural weakening |

Roof Panels | Withstands solar radiation + fire |

Industrial Ductwork | Prevents heat transfer + ignition |

In the UAE, my client Lala demanded fire-retardant materials for a new logistic center. Traditional fiberglass just wouldn’t do. We supplied aerogel felt rolls that met both the ASTM E84 and EN 13501-1 standards. The result? Better safety rating, and lower insurance premiums.

So if your project includes risks like open flames, welding work, or heat exposure, this felt adds more than just insulation—it adds safety.

Why Is Aerogel Felt Ideal for High-Temperature Environments?

I’ve worked with engineers who doubted that anything could survive at 600°C daily. But that’s where aerogel felt proves its worth.

Aerogel fiberglass felt performs exceptionally well in extreme heat conditions, making it ideal for furnaces, kilns, refineries, and other high-temperature industrial zones.

It doesn’t melt, shrink, or degrade like other materials. This means your insulation doesn’t need constant replacement, which lowers your long-term operating costs.

Temperature Resistance Comparison

Material | Max Operating Temp. | Thermal Shrinkage Risk |

Aerogel Felt | 1000°C | Very Low |

Rock Wool | 650°C | Moderate |

Fiberglass Blanket | 500°C | High |

One of our clients in Malaysia, Mr. Wu, uses aerogel felt inside factory boiler rooms. He used to change insulation every year due to shrinkage and cracking. Now, he only needs minor checks during scheduled maintenance. The reliability here translates directly to business efficiency.

When projects demand continuous high-heat operation—like chemical processing or power plants—this material isn’t just suitable. It’s essential.

Is Aerogel Fiberglass Felt Suitable for Energy-Efficient Buildings?

When I first heard of "net zero" buildings, I thought they were more about fancy design than real savings. Turns out, insulation makes a huge difference.

Aerogel fiberglass felt supports energy-efficient buildings by reducing heat loss, controlling indoor temperature, and minimizing HVAC usage—all while using less material thickness.

In warm regions like the Middle East or Southeast Asia, air conditioning is a major cost. Traditional insulation might help a little—but not enough.

How It Helps in Green Building Projects

Benefit | Description |

Thin but Strong Barrier | Achieves better R-value in less space |

Low Air Permeability | Minimizes thermal bridging |

Eco-friendly Manufacturing | Contains no formaldehyde or toxic additives |

Compatible with Green Labels | LEED, BREEAM, and other certifications |

Several developers have told me their wall structures are too thin for bulky insulation. Aerogel felt solves that. You don’t need to redesign the wall. Just use thinner, better-performing insulation.

It’s also easier to transport and install, reducing labor costs and carbon footprint. In one of our projects, switching to aerogel helped the building get a local green certification, which improved resale value.

Conclusion

Aerogel fiberglass felt isn’t just another insulation product—it’s a solution for modern, safe, and energy-efficient construction.

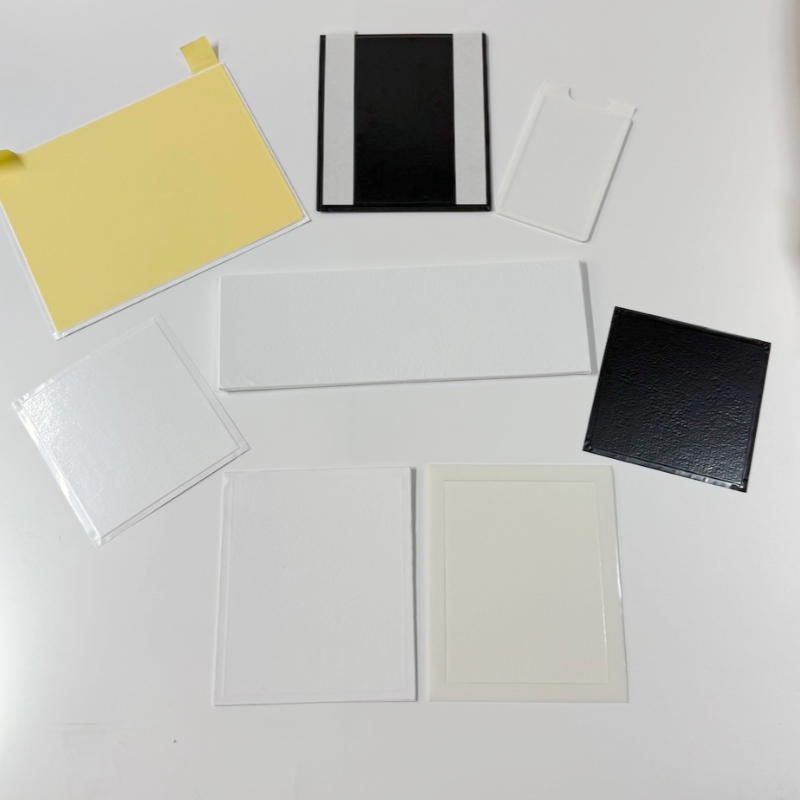

Ceramic Fiber Chemical Film-Fo...

Ceramic Fiber Chemical Film-Fo...  Wet-process Glass FiberAerogel...

Wet-process Glass FiberAerogel...  Needle-Punched Glass FiberAero...

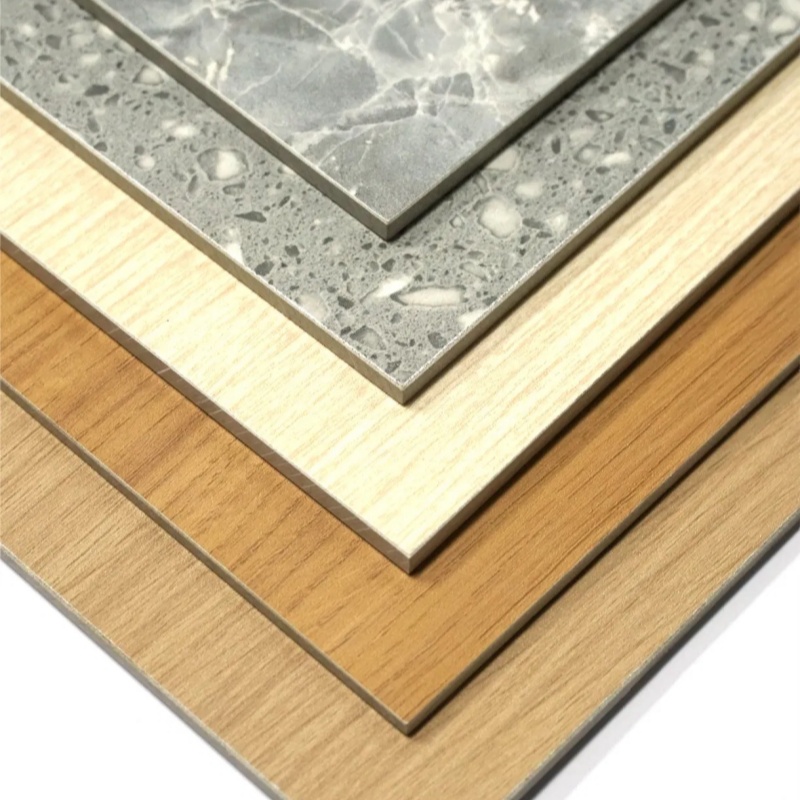

Needle-Punched Glass FiberAero...  Aerogel Panel

Aerogel Panel  OEM Cherry Wood Grain Antibact...

OEM Cherry Wood Grain Antibact...  Cement-Based Aerogel

Cement-Based Aerogel  Aerogel Fireproof And Heat-Ins...

Aerogel Fireproof And Heat-Ins...  Thermal Insulation Integrated ...

Thermal Insulation Integrated ...  New Energy Vehicle Battery Cor...

New Energy Vehicle Battery Cor...  Aerogel Explosion-Proof Fire B...

Aerogel Explosion-Proof Fire B...  Water-Based Aerogel

Water-Based Aerogel